Don’t be victim of DTV: problems, solutions & prevention

Top 5 tips to takeaway

Scott Irwin, Head of Technical Training at Textar, a leading global manufacturer of brake friction products, advises his top tips for brake replacement success.

- DTV occurs when the thickness of the brake disc is not even.

- DTV usually only appears after a few thousand kilometres.

- DTV can cause driver discomfort including noise and vibration. Over time this could lead to more serious complications for the overall braking performance.

- The thinnest and the thickest point in the brake disc must not exceed 0.015mm and, in the case of sensitive chassis, 0.008mm.

- Taking just a little more time during the brake replacement process to properly clean and check the runout will reduce the risk of DTV.

What is DTV?

Disc thickness variation (DTV) occurs when the thickness of the brake disc is not even, making a noticeable difference when the brake pedal is applied. It can be avoided by performing some simple yet effective steps within the brake replacement process, however, it can often be overlooked if there are time constraints.

The difference between DTV and lateral runout

DTV is sometimes mistaken for lateral runout when trying to determine the cause of vibration or judder. It’s important to note that the symptoms are similar. In both cases, there are steering wheel vibrations or pedal pulsation.

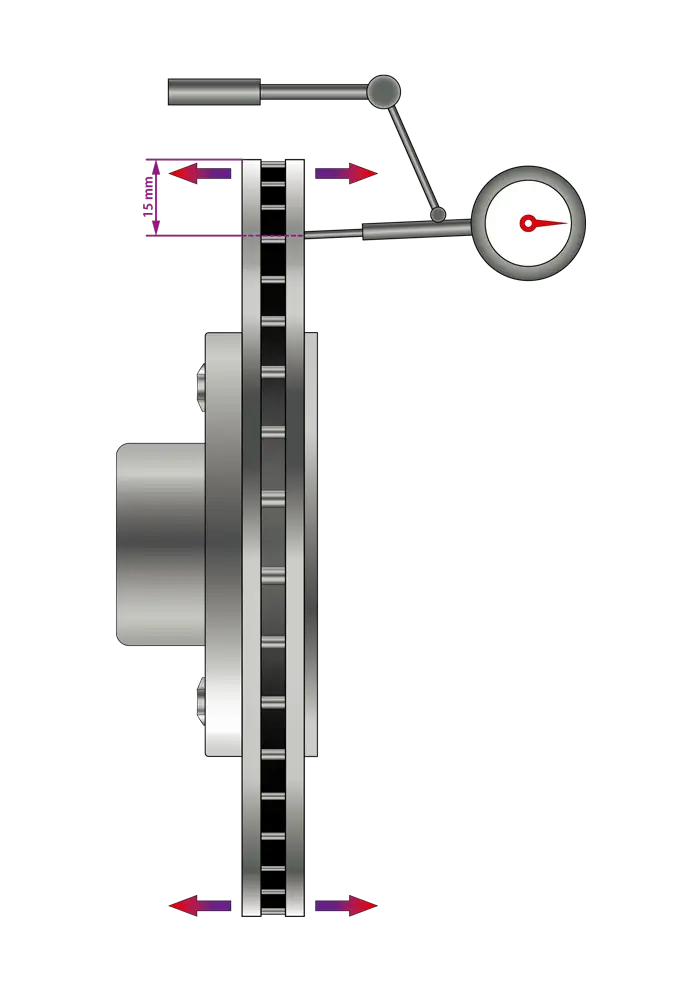

The classic lateral runout, which may not exceed 0.07mm when installed or 0.04mm in the case of very sensitive chassis, usually becomes noticeable during the bedding-in phase.

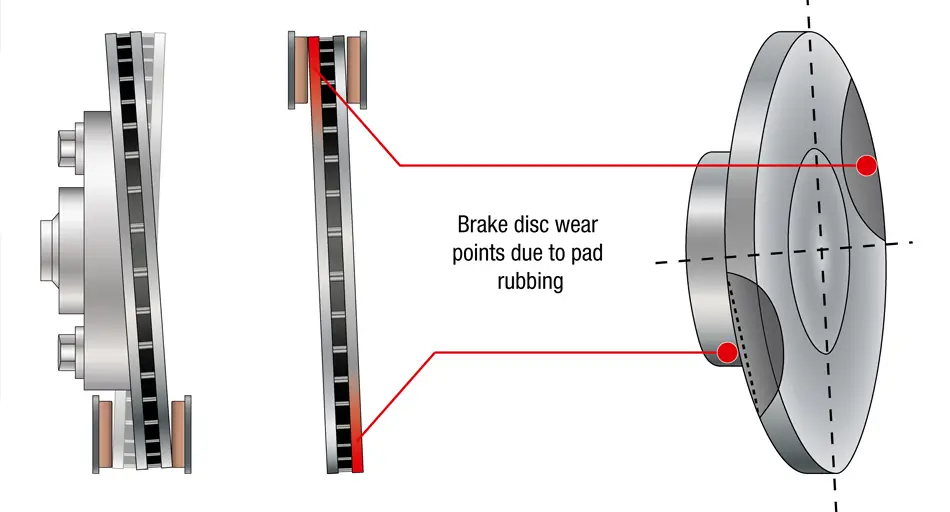

Whereas DTV usually only appears after a few thousand kilometres, as it is caused by unintentional contact between the brake pad and the brake disc in the unbraked state, leading to washouts in the brake disc. The difference between the thinnest and the thickest point in the brake disc must not exceed a value of 0.015mm and, in the case of sensitive chassis, 0.008mm.

What causes DTV?

The consequences of DTV

How to prevent DTV

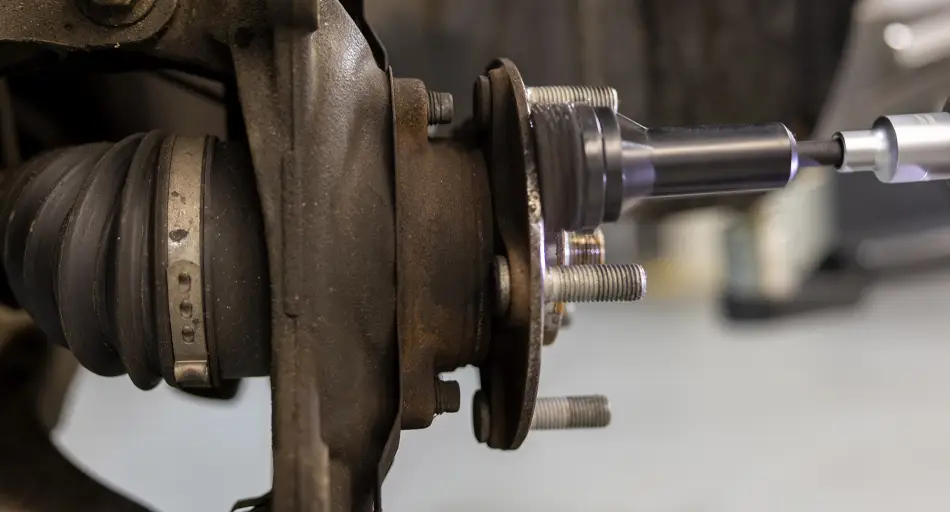

It’s essential to ensure the contact surfaces and caliper are dirt and rust free, as insufficient cleaning can result in the occurrence of brake judder. Mechanics should use a wire brush or hub grinder/over stud cleaning tool to remove any rust deposits from the hub, while taking care not to damage it or the calipers.

Once a thorough clean and inspection of the hub and surrounding area is complete, it’s time to fit the new brake disc. Once in place, a dial gauge should be used to check for any potential lateral runout. It’s important to make sure disc runout doesn’t exceed 0.07mm, as this can have consequences on the entire braking system and can cause vibrations through the steering wheel and also the brake pedal.

Taking just a little more time during the brake replacement process to properly clean and check the runout can make a significant difference in the overall job and performance of the brakes. Whilst it can be easy to miss this step out during busy periods, more time will be spent trying to find the fault if a customer comes back with the complaint. Following best practice from the initial brake replacement will ensure the brakes perform as intended, resulting in a happy customer with no return visits.

About TMD Friction

TMD Friction is a leading global supplier of high-quality brake friction solutions to the automotive and brake industries. The company develops and manufactures disc brake pads and drum brake linings for passenger cars and commercial vehicles.

TMD Friction supplies vehicle manufacturers with premium products for original equipment, as well as being a driving force in the international aftermarket with the brands Textar, Mintex, Don, Pagid, Cobreq, and Bendix. The product portfolio also includes brake friction products for motor racing under the Pagid Racing and Mintex Racing brands and for industry applications under the Cosid brand.