Premium Brake pads and Linings

FOR TRUCK, TRAILER,

BUS OR COACH

Textar offers disc brake pads and drum brake linings for 100% of all European commercial vehicles. And with Textar, every product comes with the assurance of total quality, maximum safety and ultimate reliability.

As the world’s leading brand for commercial vehicle brake friction and the leading supplier of brake pads and linings to both the OE sector and the aftermarket, Textar offers the performance and safety that only the original can guarantee.

That’s why 70% of all commercial vehicles in Europe are fitted with Textar brake linings as standard.

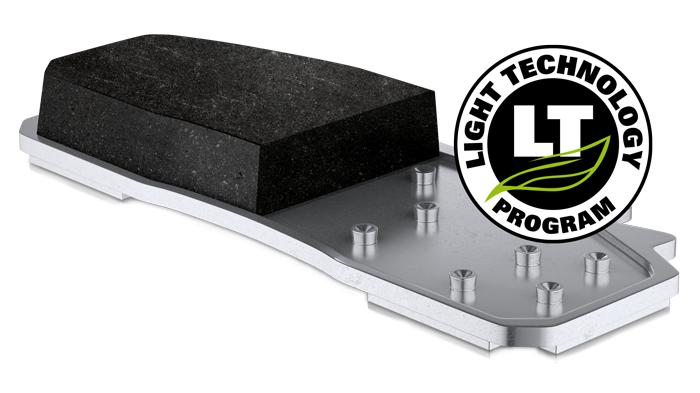

Driving innovation: Textar’s new lightweight disc brake pads combine safety with sustainability. Their ultra-strong, yet lightweight design contributes to lowering fuel consumption and emissions, so they’re better for you and for the environment, too.

WE GO TO THE LIMIT.

SO THAT YOU DON’T HAVE TO.

Lighter vehicle components help to reduce vehicle weight – which in turn leads to fuel savings and lower CO2 emissions. TMD Friction is the trailblazer in this sector and Textar brake pads manufactured with the new lightweight backing plate from TMD Friction’s Lightweight Technology Program are lighter than conventional commercial vehicle brake pads whithout compromising safety.

The advantage for fleet operators: Textar’s lightweight brake pads utilize the same geometry as standard brake pads, so they’re a direct replacement fit. Making this simple change to lightweight brake pads can contribute to an overall reduction in vehicle weight and an improvement in fuel consumption that can realise noticeable fuel savings over the service life of a commercial vehicle.

PREMIUM BRAKE TECHNOLOGY

COMMERCIAL VEHICLE BRAKE PADS

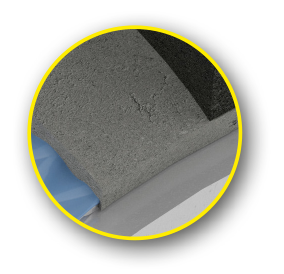

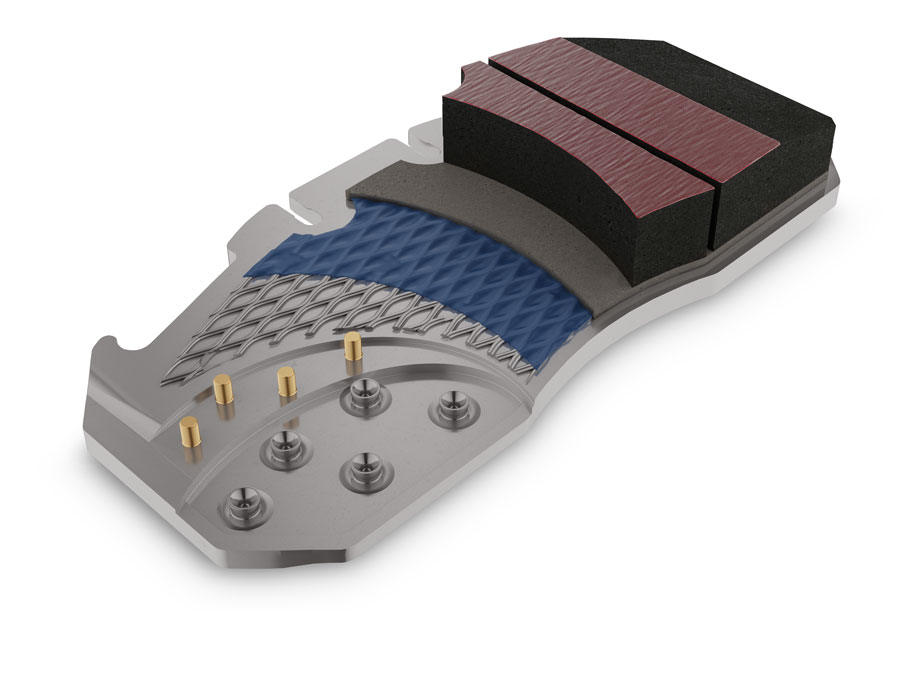

Groove

Reduces material tension and increases resistance to material cracking due to thermal stress.

.

Surface coating

Surface coating ensures safe braking from the first stop.

Chamfer

Improves embedding process and comfort behaviour.

Friction material

Application specific friction material.

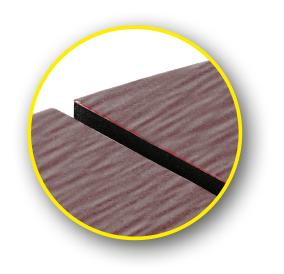

Underlayer

Provides optimised bonding properties between the backplate and friction material as well as good thermal insulation and noise reduction properties.

Cast iron backplate

Advanced design that allows for mechanical retention systems such as pins to be included. The advantages are reduced weight as well as improved heat transfer and noise characteristics.

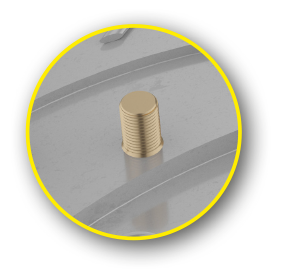

Brass pinned backplate

Greatly increases the material bond between material and steel backplate.

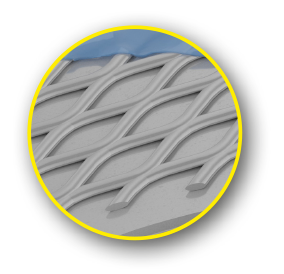

Meshed backplate

Provides a good retention for the underlayer and improves material shear resistance.

Adhesive

Ensures the necessary connection between friction material (underlayer) and backplate.

.

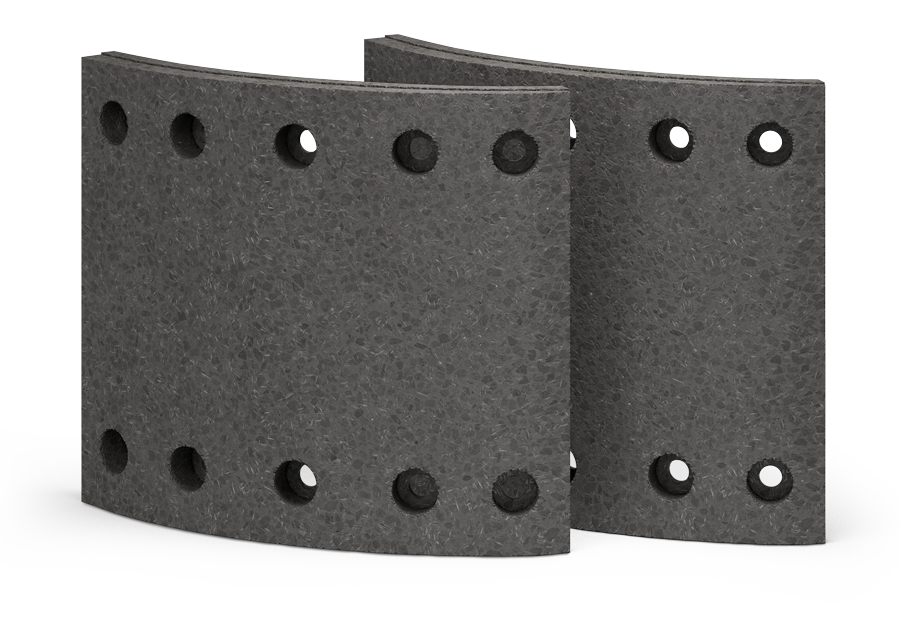

BRAKE LININGS

FROM THE LEADING OE SUPPLIER

Textar drum brake linings for commercial vehicles provide highest quality due to friction materials perfectly tailored to the application.

Manufactured to the highest standards in our own production sites and tested extensively. This is how we ensure premium quality and durability. And for fleets, this means less downtime and more time on the road.

- Manufactured to highest standards in our own sites

- Extensive testing to ensure premium performance

- Extended lifetime through minimal drum wear

- No. 1 OE brand for commercial vehicle brake friction