Premium

Brake Discs

INTELLIGENT DESIGN. DOWN TO THE LAST DETAIL

The optimum braking result can only be achieved with brake discs precisely tailored to the brake pad. It is this philosophy that has also made us experts in terms of the right “friction partner” for our brake pads.

The Textar brake disc range is manufactured in strict accordance to O.E. tolerances and meets the ECE R90-requirements. The range comprises over 1.650 references for the passenger car sector and covers virtually 100% of the European car parc.

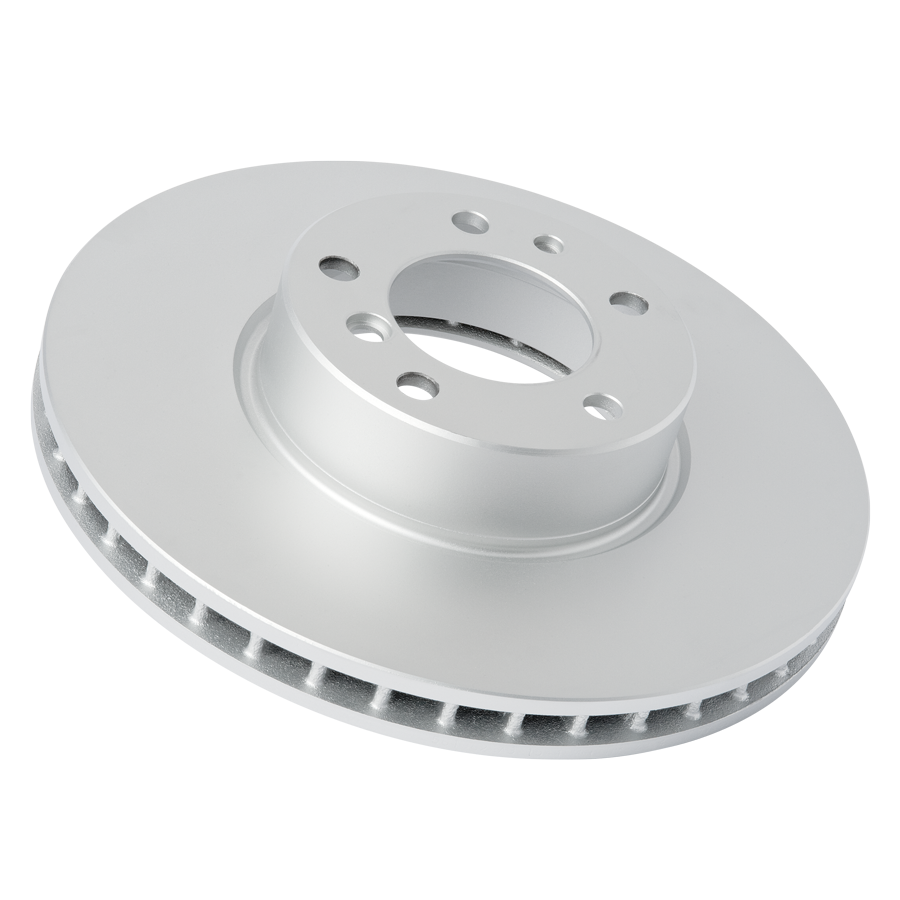

Fitment surface

Precision machined turned within O.E. tolerances;

for perfect assembly.

Heat channel

Directs heat transfer to the disc ventilation chamber; improves heat dissipation and provides anti-vibration performance benefits.

Friction surface

Manufactured within O.E.

tolerances; precision machined.

Permanent marking

Embossed: manufacturer,

part number, minimum thickness.

Cooling ventilation

Optimized heat dissipation via

bridges, columns, or blades (right/left).

High tech metallurgy

Special casting process delivers extremely homo –

geneous material surface;

depending on disc type

with anti-corrosion coating.

brake discs for every application

explore our portfolio

Two-piece composite brake discs

Cast iron meets aluminium

Brake discs with wheel bearing and ABS sensor ring

All three made easy.

Brake discs with wheel bearing

Two elements. One unit.

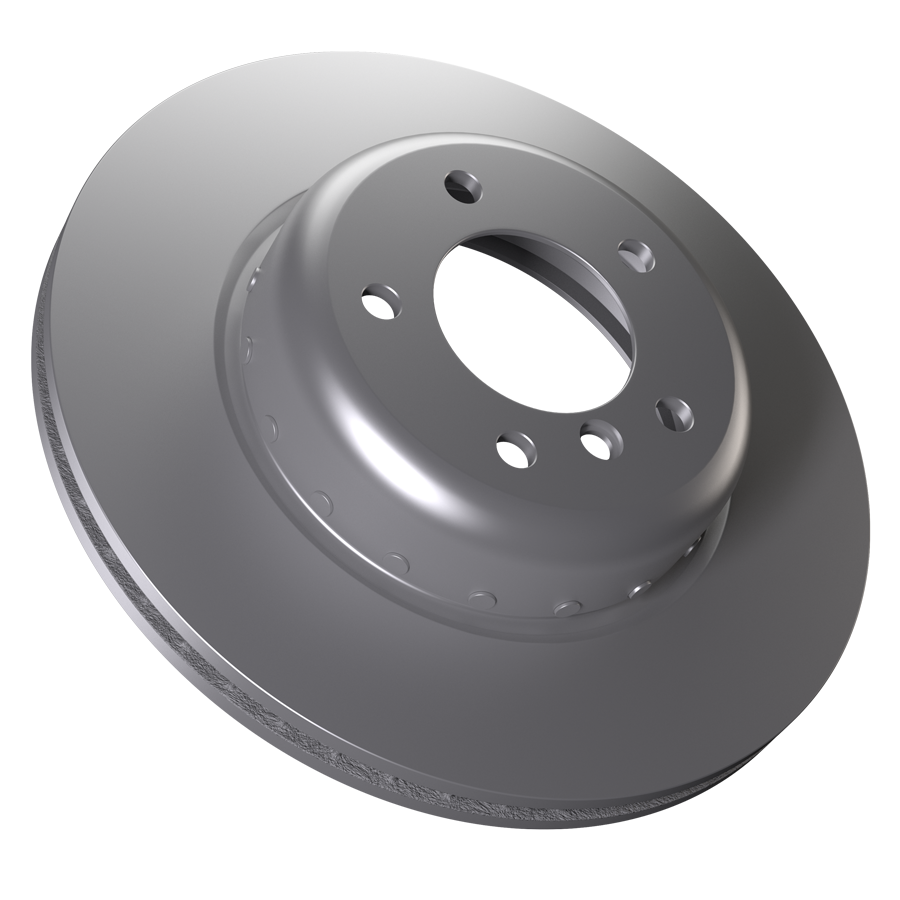

Coated brake discs

A better aesthetic. Pro.

Coated brake discs, high carbon

More know-how. Pro+

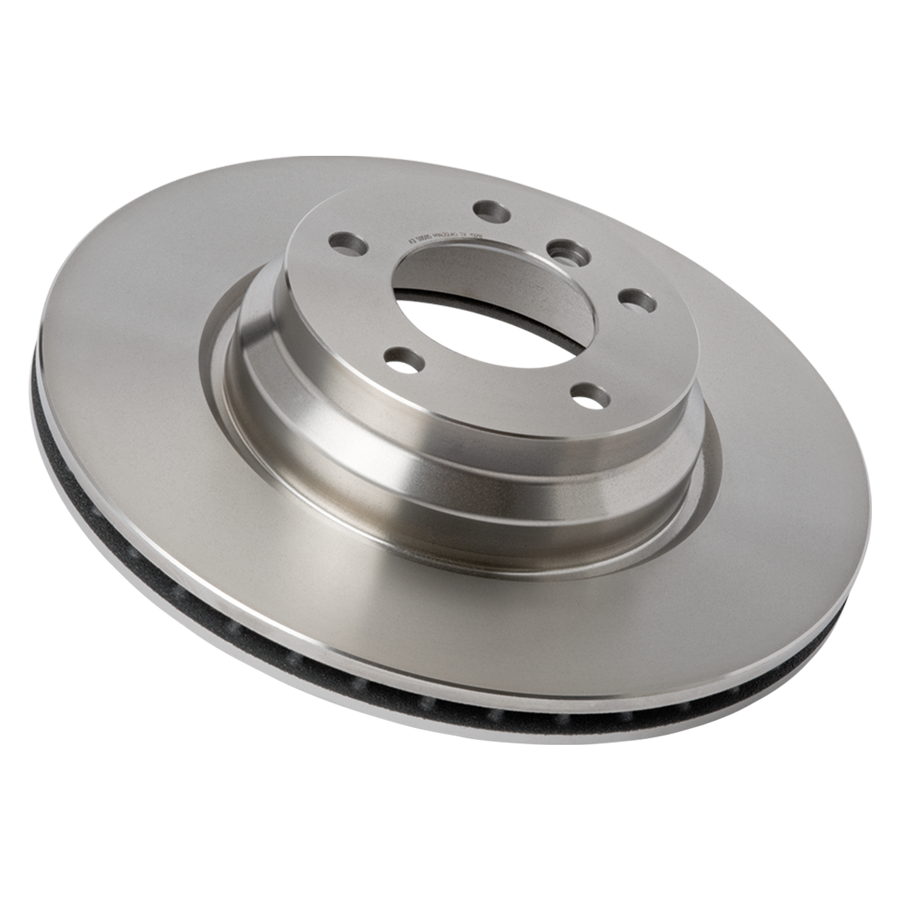

Uncoated brake discs

Quality. For every requirement.