LIGHTWEIGHT BRAKE PADS

Whether in the OE sector or in the aftermarket – a high percentage of commercial vehicles worldwide are fitted with Textar brake friction, TMD Friction’s premium brand. This success is based on our range of products perfectly tailored to the different vehicles and brakes and our strong focus on research and development.

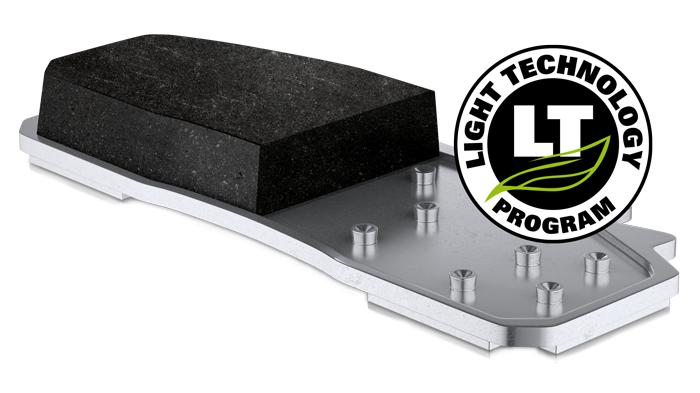

As the first aftermarket brand, Textar is now presenting another innovation – lightweight brake pads for commercial vehicles developed in the “TMD Friction Light Technology” program.

HEAVY ARGUMENTS FOR LIGHTWEIGHT DESIGN.

All Products are tested via our in-house R&D team:

The challenge of heavy goods trucks in motion is the mass that needs to be accelerated, and stopped again as quickly as possible in an emergency. This results in high fuel consumption and excessive wear of the brake pads. Any reduction in weight saves costs and, at the same time, protects the environment. However, a brake pad is a relatively small component and, consequently, offers little room to achieve this technically.

Nevertheless, our engineers have succeeded in reducing the weight without changing the pad geometry and without impairing the efficiency of the brake pads. Therefore, the standard pads used up to now can be replaced with the innovative light-weight brake pads from Textar without difficulty.

NO CHANGE IN GEOMETRY

FIT AND DISCOVER THE BENEFITS.

APPLICATION-SPECIFIC FRICTION MATERIAL,

UNCHANGED DIMENSIONS

UNDERLAYER COMPENSATES THINNER BACKING PLATE

WEIGHT-OPTIMISED BACKING PLATE

SAVING MADE EASY

This innovation is based on a thinner and, thus, lighter backing plate for commercial vehicles, manufactured in the “TMD Friction Lightweight Technology” program. The slimness of the backing plate is compensated for by an underlayer which has a lower specific weight than steel, while durability and load-bearing capacity of the plate remain the same. Wear on the brake/axle system is minimised due to the reduced weight.

On a 6-axle truck/trailer combination, up to 7.5 kg in weight can be saved. Fuel consumption and CO2 emissions are reduced as a result, increased revenue can be generated by additional loading. This pays off for the forwarding agent.